- Home

- /

- Products

- /

- Blasting Products

- /

- MTi Group Open Pit

- /

- BlastShield

BLASTSHIELD™

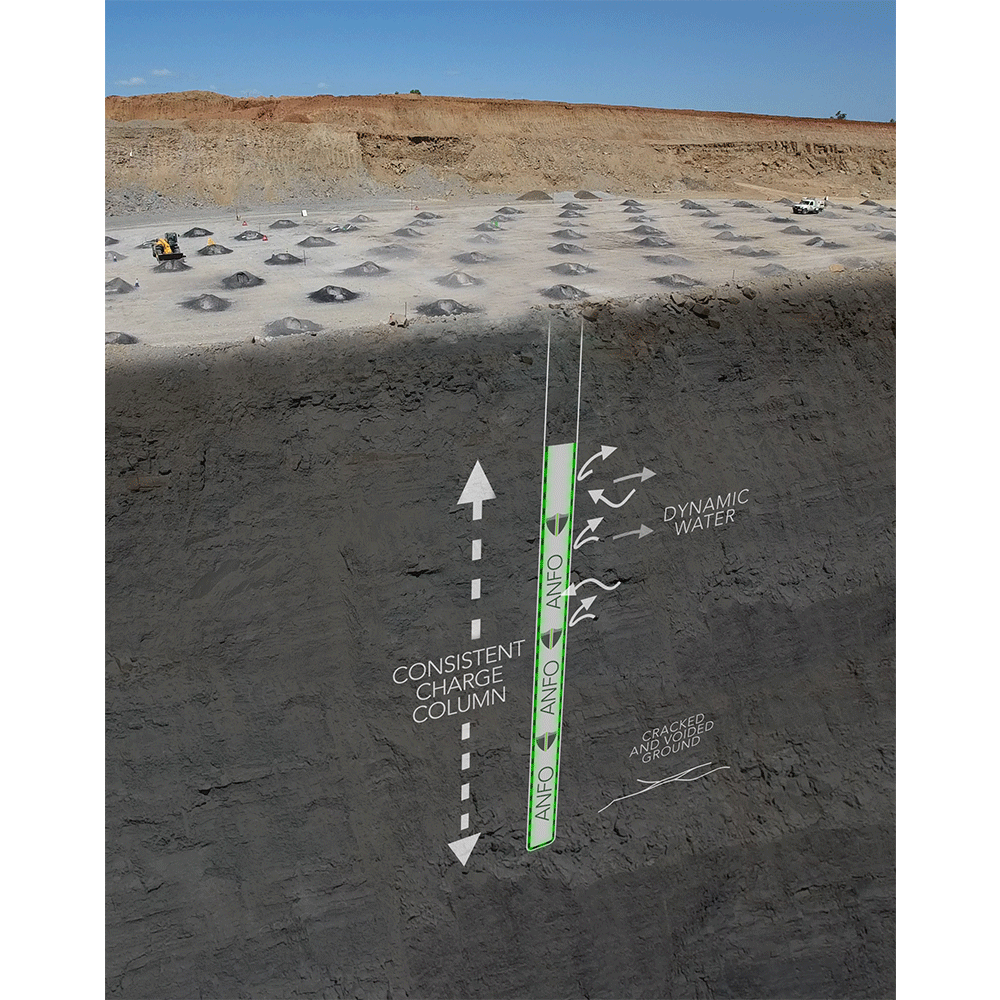

Blasthole liners provide an impermeable barrier between the explosives and the environment keeping contaminants from ingressing into the explosives and from explosives seeping into the environment.

In combination with engineered explosive formulations, blasthole lining provides a solution to blasting related environmental issues.

BLASTSHIELD™ |

CONVENTIONAL |

|

APPLICATION |

|

|

RELIABILITY |

|

|

SAFETY |

|

|

Features

Easy to use

Linear meter marks to assist lining

Durable – High tensile

Rip stop composite laminated fabric

Strength to weight optimized

Gusseted and seamless

Gusset prevents twists and makes insertion easy

Seamless material with no weak points

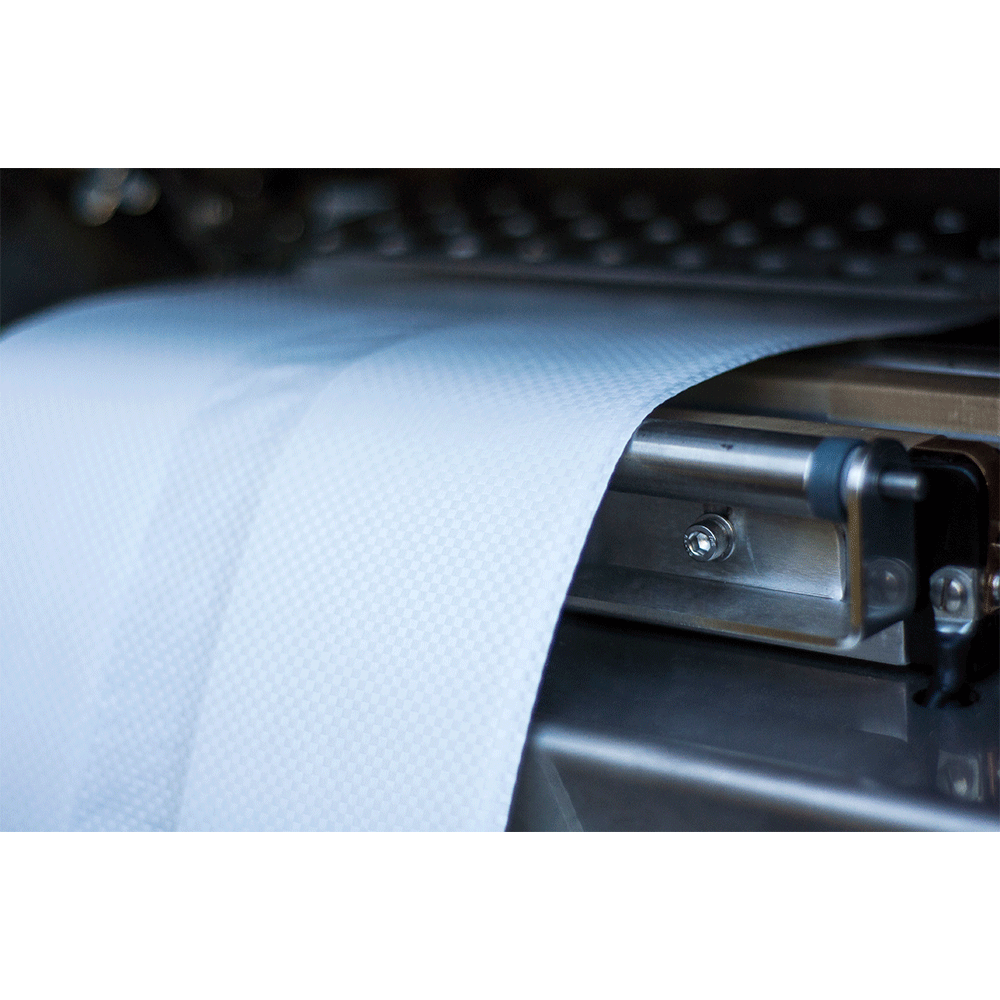

Bulk easy change Rolls

350m per roll, lightweight and easy to handle

12V BLASTSHIELD SEALER

Sealing machine for mobile equipment

Aside from eliminating blast fumes Blastshield can….

- Avoid overloading and loss of explosives where cavities, UG workings or preconditioned benches exist

- Match explosives to the ground type

- Improve blast outcomes such as fragmentation due to better performing explosives

- Increase sleep times of blasts reducing mine downtime