- Home

- /

- Products

- /

- Mining – General

- /

- Advanced Stoper – Long...

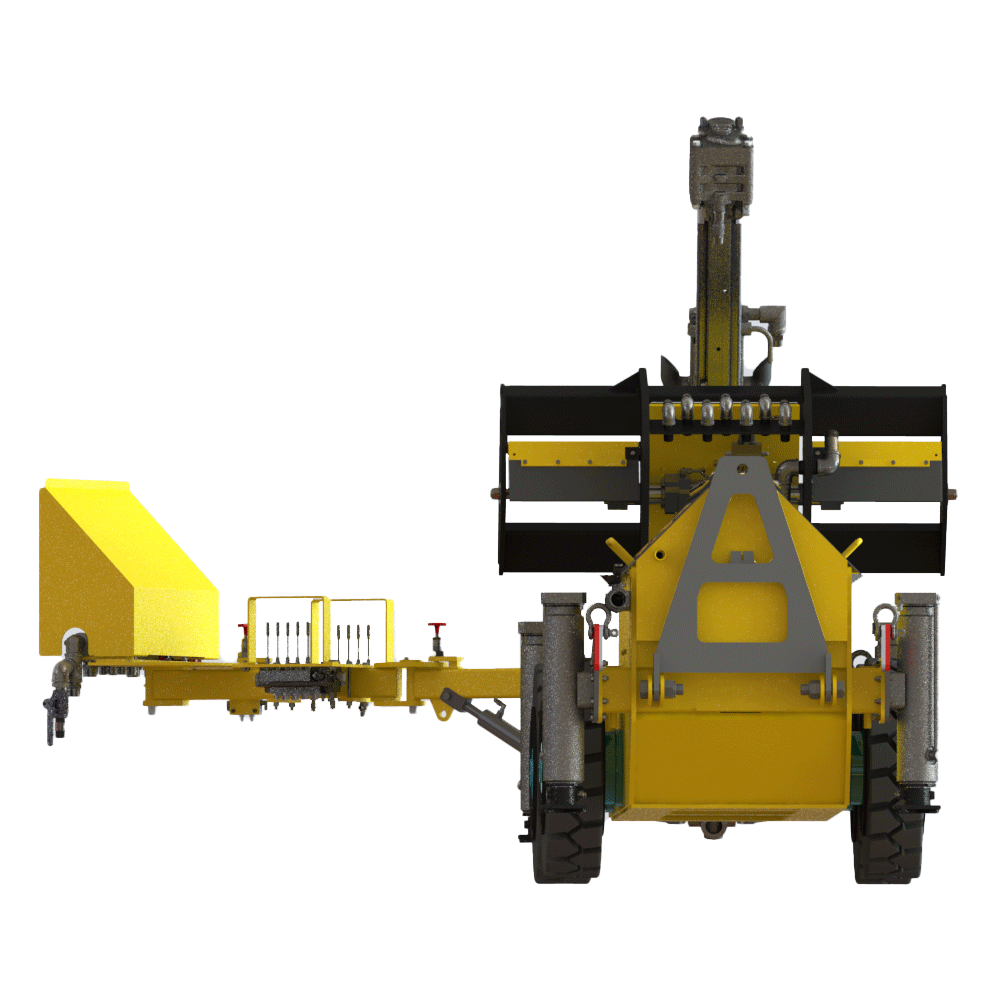

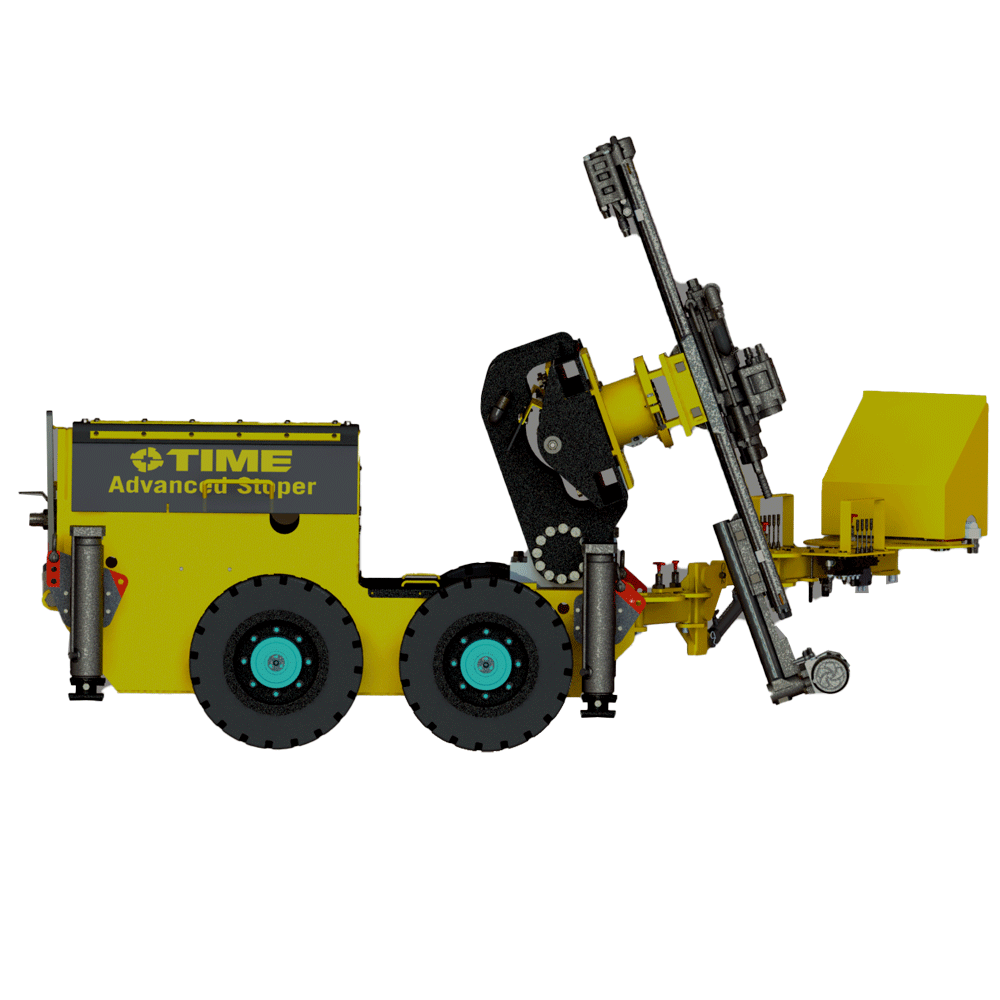

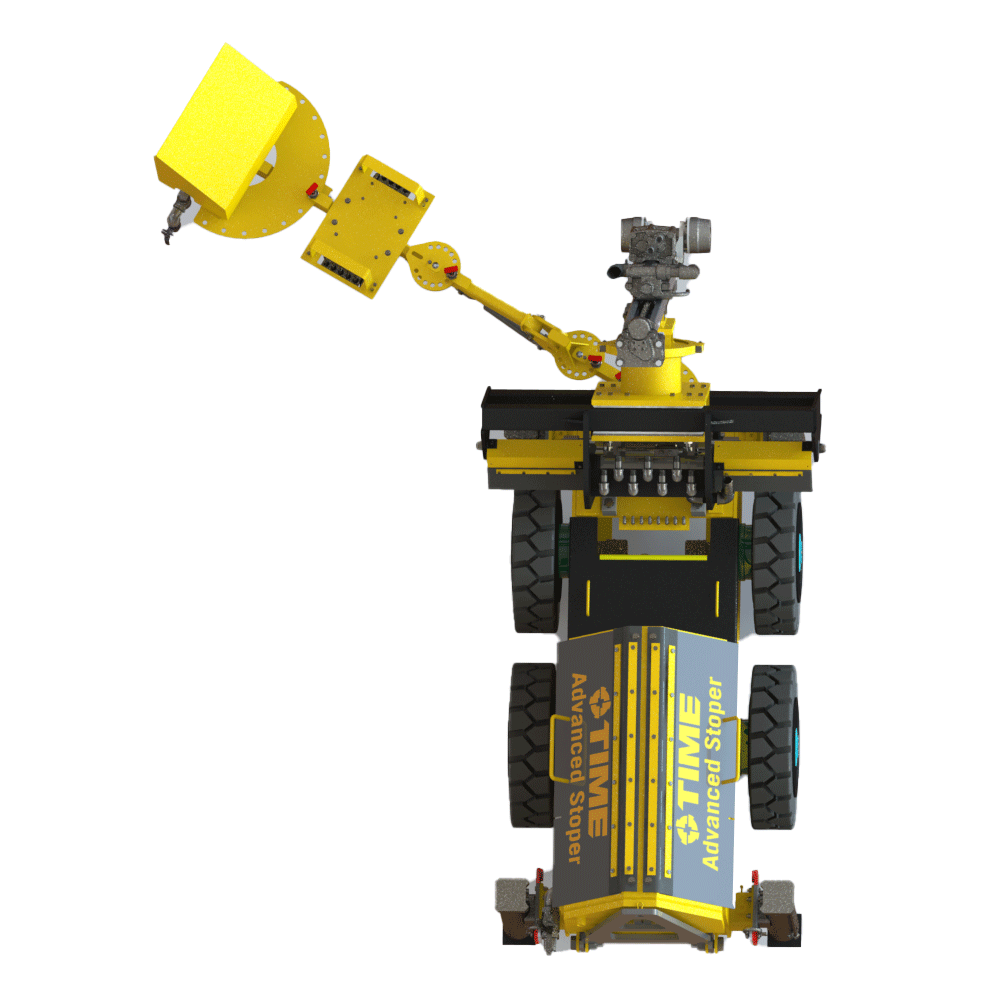

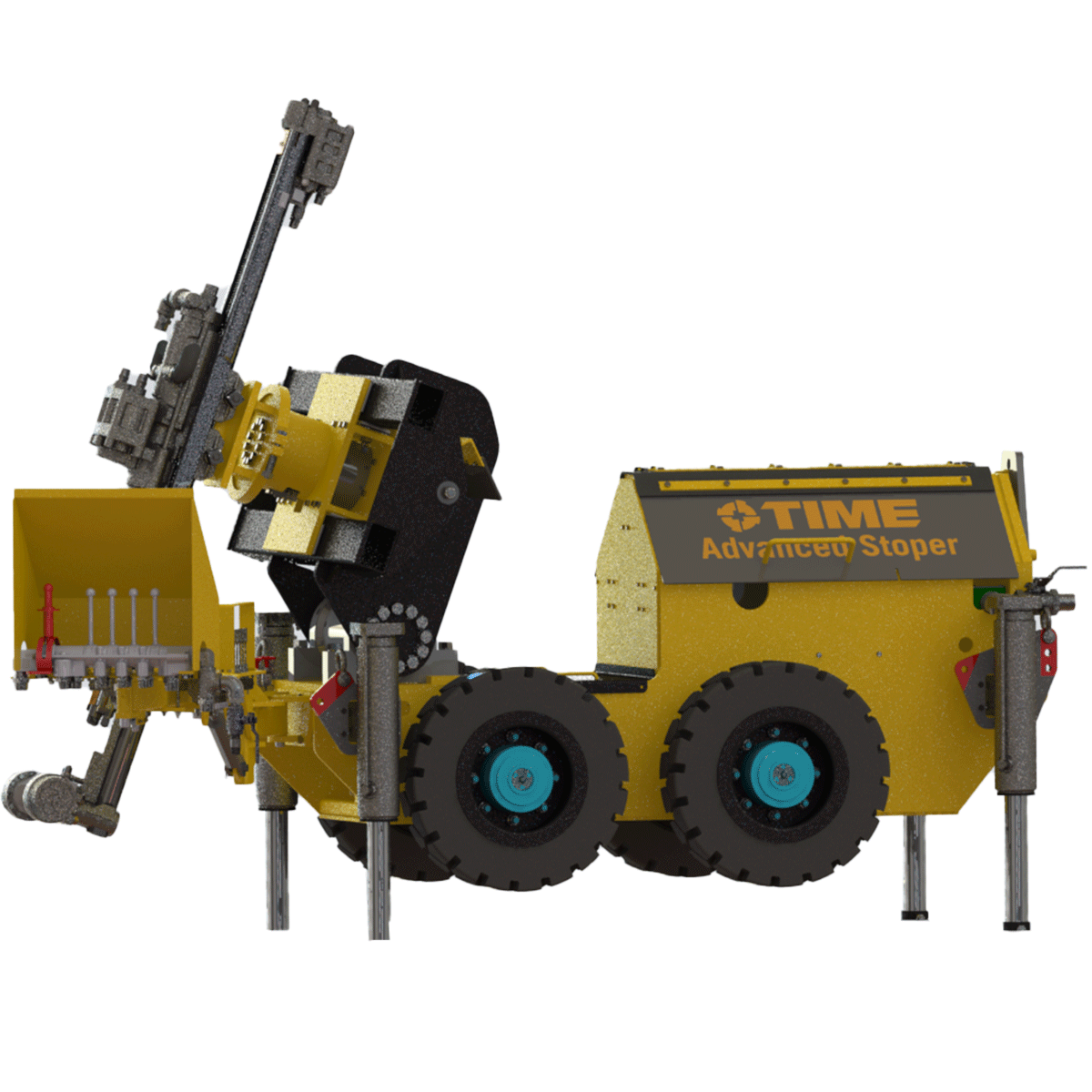

TIME Advanced Stoper

Long hole Drill

The Advanced Stoper is a hydraulically driven drill carrier system designed to be equipped with a pneumatic drill. The drill carrier system was designed with the purpose of advancing current technologies in the field of underground drill carrier buggies. As a result, the Advanced Stoper was designed with three specific objectives:

- Maximize stability and control in drilling by increasing the weight and stabilizing the structure of the machine. This allows for the greatest transfer of pneumatic power directly to the bit, which increases productivity and helps ensure drilling accuracy. As a result, this also limits vibration in the carrier itself and thus reduces overall

wear and tear. - With the addition of three rotary actuators (135° Dump, 360° Radial and an optional 180° Pivot Positioning), the drill can be positioned at virtually any angle.

- Reduce overall maintenance costs. The reduction in maintenance is essentially a by-product of the stability of the drill. Less vibration allows for less wear and tear on the machine itself. Also, the utilization of helacs means there is no costly cylinder pins and bushings to maintain.

CARRIER FEATURES AND COMPONENTS

- Radial piston air motor, 30hp @1200 rpm, 116psi & 890cfm air delivery

- Tandem gear hydraulic pump, 1.91 cu. in. per rev. @3000psi

- High quality proportional directional control valves

- High quality motion control and cross-port check valves

- Two lever pilot (low) pressure tethered remote tramming valve

- Skid steering with independent port and starboard wheel drives

- Planetary 4 wheel hydraulic drive with fail-safe brakes

- 4 independent heavy duty jacks with load lock (cross port check) valves for leveling

- Tow-bar and dis-engaging wheel drives for towing

DRILL POSITIONING

- 135° drill position dump from horizontal transport position to 45° over-center positioning with high quality rotary actuator

- Side to side hole positioning of 66” [168cm] on a 5-foot traverse with telescopic cylinder

- Side to side hole positioning of 90”[229cm] on a 7 foot optional traverse with telescopic cylinder

- 360° radial drill feed positioning with high quality rotary actuator

- Optional 180° pivoting drill feed positioning for maximum reach on left and right with high quality rotary actuator

- S36IR Rock Drill Assembly with aluminum feed and heavy duty centralizer.

PRODUCT LISTING:

| PART # | DESCRIPTION |

|---|---|

| AS10100 | ADVANCED STOPER ASM COMPLETE 5' TRAVERSE W/ S36 |

| AS10200 | ADVANCED STOPER ASM COMPLETE 7' TRAVERSE W/ S36 |

TIME Advanced Stoper Flyer

TIME Advanced Stoper Flyer